The landscape of manufacturing is constantly evolving, and as we step into 2024, it's crucial to explore the emerging trends shaping the industry's trajectory. Manufacturing, a cornerstone of the global economy, continues to be influenced by technological advancements, economic factors, and a growing emphasis on sustainability. In this blog post, we will delve into the current state of manufacturing, the trends dominating the sector in 2024, and the growth opportunities that lie ahead.

As of 2023, the industry has witnessed significant advancements in technology, with a notable rise in automation and artificial intelligence (AI). According to the World Economic Forum, automation is expected to create more than 12 million jobs by 2025, underscoring the transformative impact of technology on the workforce.

Moreover, economic factors such as geopolitical tensions and the ongoing global pandemic have prompted a reevaluation of supply chain strategies. Companies are increasingly seeking resilient and agile supply chains to navigate uncertainties, leading to a paradigm shift in global manufacturing dynamics.

Manufacturing trends emerging in 2024

1. Digital twins and smart manufacturing

Real-time monitoring and analysis are becoming integral to manufacturing processes through the implementation of digital twins. Siemens, a global technology conglomerate, employs digital twin technology to generate virtual duplicates of tangible systems. This allows for precise monitoring and optimization, leading to improvements in predictive maintenance and overall operational efficiency.

2. AI-powered content generation

Industrial manufacturing witnessed the rise of AI, particularly in machine learning and deep learning neural networks. These robust AI tools facilitated in-depth data analysis, empowering manufacturers to make sophisticated, data-driven decisions and accelerate product-related content creation for a more agile go-to-market approach.

3. 3D printing and additive manufacturing

The rise of 3D printing and additive manufacturing is reshaping traditional production methods. According to a report by Deloitte, the global 3D printing market is expected to reach $51 billion by 2025. Companies like General Electric are leveraging 3D printing to manufacture complex components, reducing waste and optimizing production processes. The application of this technology extends across various industries, from healthcare to aerospace.

Source: General Electric

4. Industrial classification standards

The industrial manufacturing sector is embracing standardized product content classification, such as ETIM and ECLASS. This shift highlights the industry's dedication to efficient product master data management for seamless content syndication to data pools and distributors. In the upcoming year, companies will intensify efforts, utilizing product content syndication to align internal data with standardized frameworks, ensuring enhanced organization and streamlined syndication processes.

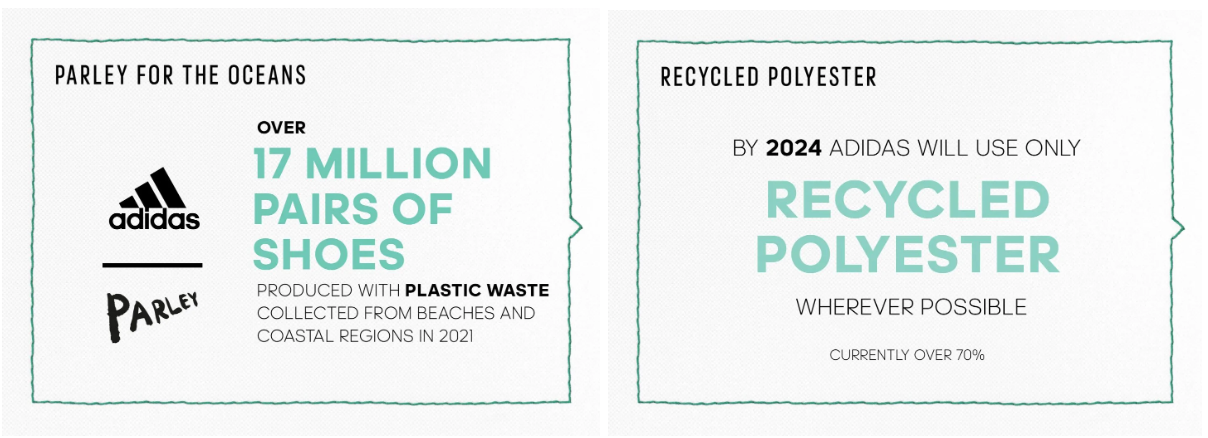

5. Sustainable materials and green manufacturing

Sustainability is no longer an afterthought but a core consideration in manufacturing. Adidas, a leading sportswear manufacturer, has committed to using only recycled polyester in its products by 2024. By incorporating eco-friendly materials into its production, Adidas is not merely diminishing its ecological impact but is also establishing a model for the industry to follow.

Source: Adidas

6. Reshoring and supply chain resilience

The disruptions caused by the global pandemic have highlighted the vulnerabilities of extensive and complex supply chains. As a response, companies are revisiting the concept of reshoring – bringing manufacturing operations closer to the consumer market. Apple, for instance, announced plans to invest $430 billion in manufacturing and research in the US over the next five years, emphasizing the importance of domestic production and supply chain resilience.

Growth opportunities in manufacturing

1. Engaging directly with end-users through omnichannel strategies

Manufacturers will actively engage directly with end-users through ecommerce and omnichannel strategies more than ever before. This evolution, encompassing both traditional B2B and direct-to-consumer (DTC) approaches, not only diversifies revenue streams but also strengthens brand presence. Manufacturers leveraging this strategy will gain valuable customer insights, enhance the customer experience, and be better equipped to respond dynamically to market trends.

2. Optimizing post-production with product content syndication

In 2024, manufacturers will shift focus to post-production efficiency, leveraging product content syndication tools, such as Productsup’s Distribution PX, to streamline the process of managing and distributing product data. These tools ensure a seamless export of customized product content, cutting costs, eliminating extensive IT support, and ultimately, enhancing the overall manufacturing process.

3. Investing in workforce development for Industry 5.0

As technology evolves, so must the workforce. Investing in the development of skills relevant to Industry 5.0 is crucial for the growth of manufacturing. Bosch, a global engineering and technology company, has implemented comprehensive training programs to upskill its workforce in areas such as data analytics, automation, and digitalization. This commitment not only improves the skills of employees but also guarantees it’s prepared for what lies ahead. Companies that embrace Industry 5.0 will optimize their workplace dynamics while also enhancing job satisfaction and overall employee well-being.

Challenges and considerations

Despite the promising manufacturing trends and growth opportunities, the industry is not without its challenges. Addressing technological gaps and skill shortages remains a priority. According to a survey by PwC, 79% of CEOs in the manufacturing sector are concerned about the availability of key skills. Bridging this gap requires a concerted effort from both the private and public sectors to invest in education and training programs that align with the demands of the evolving industry.

Regulatory and compliance issues also pose challenges for manufacturers. Striking a balance between innovation and adherence to regulations is essential for sustainable growth. Governments and regulatory bodies play a crucial role in creating frameworks that encourage innovation while ensuring ethical and responsible manufacturing practices. By partnering with Distributor Data Solutions, Productsup empowers manufacturers and distributors to scale perfect product content globally.

Manufacturers must also adapt and respond to the various needs of various data pools and wholesale distributors. This necessitates the development of capabilities for live data exchanges, ensuring that product content is not only standardized but also dynamically updated. This agility is crucial for facilitating a faster and more efficient flow of information across diverse platforms and partners.

The trends shaping 2024 and beyond reflect a commitment to efficiency, resilience, and responsible practices. As manufacturers navigate this dynamic landscape, the integration of advanced technologies and a dedication to sustainability will undoubtedly play pivotal roles in shaping the industry's future. By embracing these trends and addressing challenges head-on, the manufacturing sector is poised for a new era of growth and innovation.

For a further deep dive into industrial manufacturing trends for 2024, download our latest guide: Top manufacturing trends coming in 2024

Learn more about how Productsup supports industrial manufacturers through our Distribution PX solution.